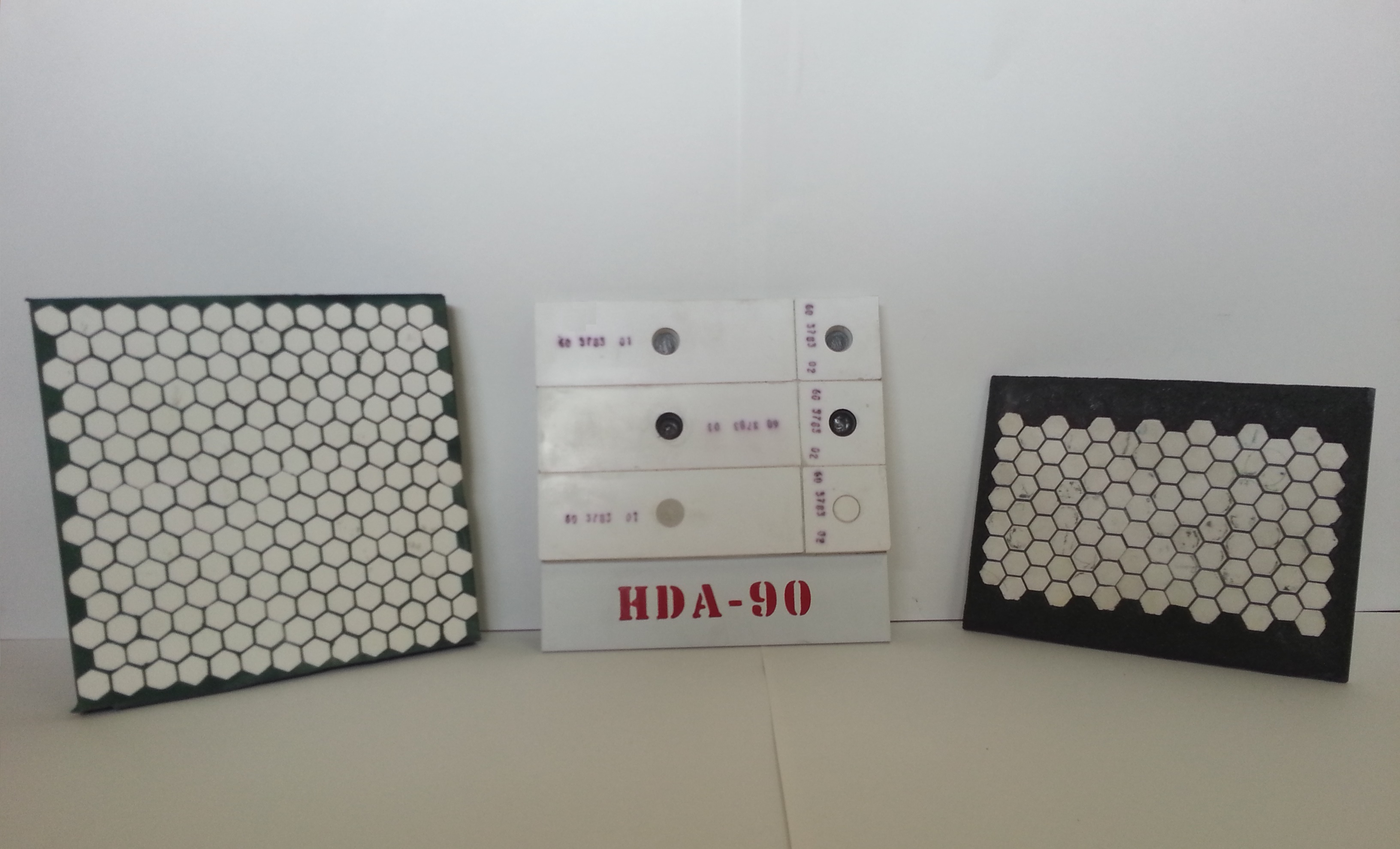

Atlas HDA-90 is a solution based on sintered, ultra-fine-grain aloxite that results in one of the most cost-effective and wear resistant materials available today. The raw material used to manufacture HDA-90 is exceptionally pure and consistently controlled alpha aluminum oxide.

HDA-90 is specifically designed for abrasion / erosion resistance, inertness towards most chemicals, retention of mechanical / chemical properties at elevated service temperatures (2000ºF). Atlas has extensive experience in the fabrication and field installation of HDA-90 to resistant extreme abrasion / erosion, severe impact and continuous chemical immersion. Our proprietary method of engineering design and installation make HAD-90 a versatile and long-lasting solution to almost any process.

HDA-90 is readily available in many standards sizes, custom engineered designs and quick-turnaround prototype development.

Features:

-

Adaptable to any surface

-

Hardness in Moh’s scale of 9 (Diamond is 10)

-

High-grade wear-resistant material

-

Smooth, non-porous finish

-

Chemical inertness

-

Retain chemical / mechanical properties up to 2000ºF

-

Many installation methods depending on operating conditions

-

Urethane Encapsulation

-

Steel Alloy Composite Bond

-

HT Composite and Weld Combination

-